ABOUT US

ABOUT US

CNC Drilling Machine

Release time:

2025-05-30

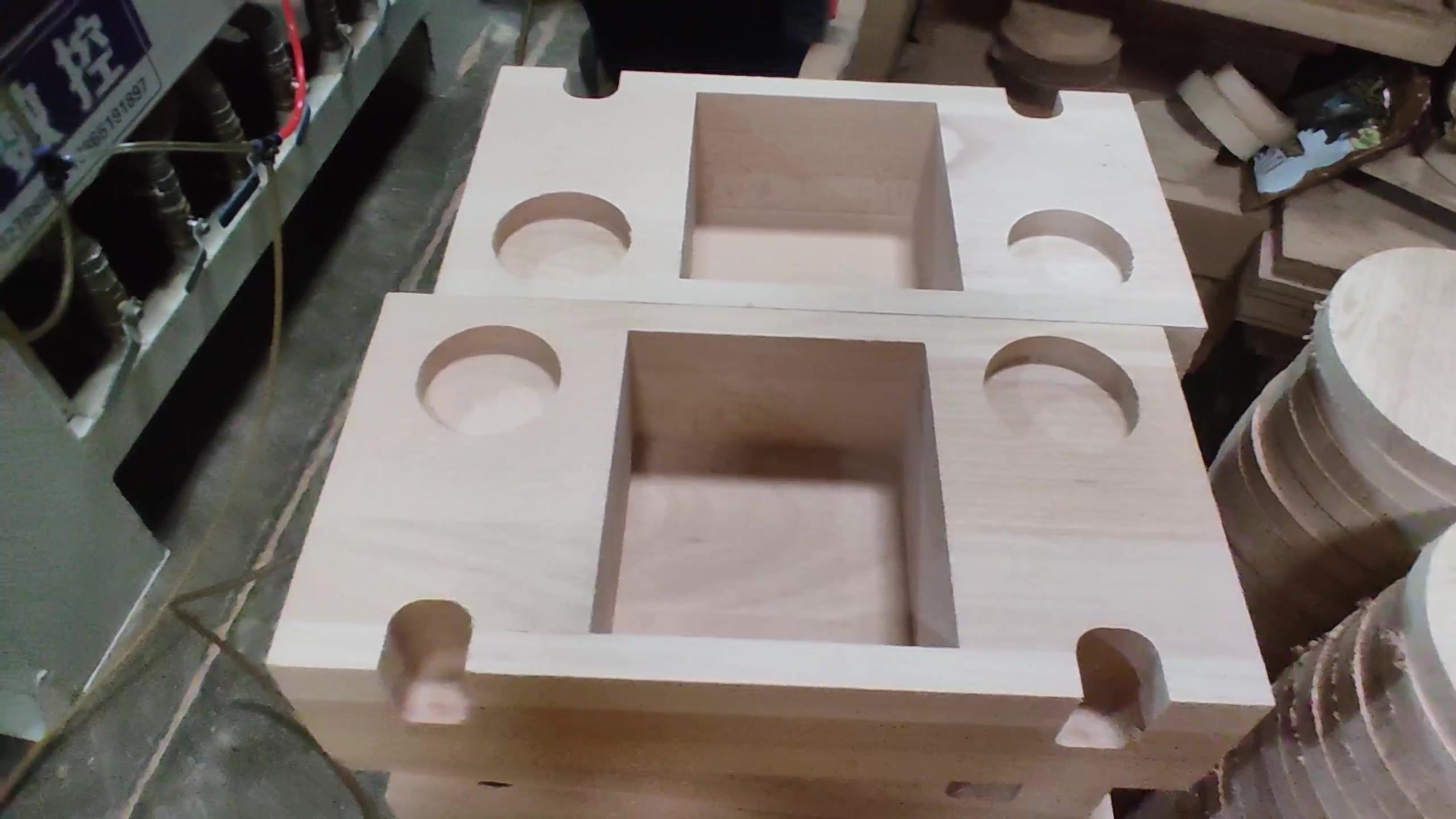

CNC Machine Hole Drilling Process: Precision Engineering for Wooden Components

In modern wooden products manufacturing, CNC (Computer Numerical Control) machines play a pivotal role in creating precise, repeatable holes for joinery, hardware installation, or structural connections. Below is a step-by-step breakdown of the CNC hole drilling process, combining advanced technology with meticulous craftsmanship to ensure accuracy and efficiency.

1. Design & Program Preparation

The process begins with CAD/CAM software (e.g., AutoCAD, SolidWorks, or specialized woodworking software like Cabinet Vision). Engineers input design specifications: hole size, depth, location, and pattern—whether for dowels, screws, hinges, or decorative elements. The software converts these designs into G-code, the digital language that guides the CNC machine’s movements. For complex projects with multiple hole types, the program optimizes drilling paths to minimize machine travel time, enhancing productivity while reducing material waste.

2. Material Loading & Fixturing

A flat, stable workpiece (e.g., a wooden panel, furniture component, or custom part) is secured onto the CNC machine’s table. To prevent movement during drilling, fixtures like vacuum chucks or mechanical clamps hold the wood firmly in place—critical for maintaining precision, especially with thin or irregularly shaped pieces. The machine’s worktable may also feature a grid of T-slots or reference points to align the material with the coordinate system (X, Y, Z axes) defined in the program.

3. Tool Setup & Calibration

CNC machines use spindles equipped with interchangeable drill bits, ranging from standard twist drills for straight holes to specialized tools for countersinks, counterbores, or mortises. Operators select bits based on hole requirements (e.g., 3mm for pilot holes, 15mm for dowel joints) and load them into the machine’s automatic tool changer. Before starting, a touch probe calibrates the spindle’s position relative to the workpiece, ensuring the first hole is drilled exactly at the programmed coordinates.

4. Automatic Drilling Operation

Once the program is launched, the CNC machine operates autonomously:

- The spindle accelerates to the specified RPM (e.g., 10,000–24,000 rotations per minute, depending on wood density and bit type).

- The table or spindle moves along the X, Y, and Z axes, positioning the bit precisely over the first drilling location.

- For through-holes, the bit penetrates fully through the wood; for blind holes, the Z-axis depth is controlled to stop just short of the bottom surface, preventing splintering.

- On multi-layered or composite materials (e.g., plywood or MDF), the machine may adjust feed rates to avoid chip-out at entry/exit points, using features like slow-start penetration or backer boards.

Modern CNC routers also integrate spindle speed sensors and force-feedback systems to detect anomalies (e.g., knots in solid wood) and adjust drilling parameters in real time, ensuring consistent quality even with natural material variations.

5. Quality Inspection & Finishing

After drilling, each component is inspected for:

- Dimensional accuracy: Hole diameter, depth, and spacing using calipers or gauging fixtures.

- Surface integrity: No splinters, tear-out, or burn marks (caused by excessive friction or slow feed rates).

- Alignment: Holes must align with mating components (e.g., ensuring a hinge hole matches its counterpart on a cabinet door).

Minor imperfections can be sanded or reamed, while critical errors trigger a program review to prevent repetition. For hardware installation, drilled holes may receive additional treatments—e.g., countersinking for flush screws or inserting threaded inserts for stronger connections.

6. Machine Maintenance & Cycle Repeat

Post-operation, the CNC machine is cleaned of wood chips and dust (using built-in vacuums or compressed air), and tools are checked for wear. The process repeats for subsequent workpieces, with the machine capable of producing identical components batch after batch—ideal for large-scale production or custom orders requiring uniform precision.

The Advantage of CNC Hole Drilling

This process combines speed (drilling dozens of holes in seconds), consistency (eliminating human error), and versatility (accommodating complex hole patterns that would be impossible by hand). Whether for high-volume furniture manufacturing, cabinetry, or artisanal woodworking, CNC technology ensures that every hole is not just a feature but a testament to precision engineering in wood products.

Related Videos

Online Message

Filing in your phone and E-mal information willhelp us to get in touch with you in time and solve your problems as soon as possible.